The high-pressure atomization spray system is an environmental protection device that pressurizes water to a certain pressure through high-pressure equipment, and then atomizes the water into small particles through a specially designed nozzle and sprays them into the air. Its working principle mainly includes the following steps:

1. Pressure treatment: Firstly, the water is pressurized to the set pressure value through a high-pressure pump. This step is crucial to ensure that the water mist can achieve effective spraying distance and coverage area.

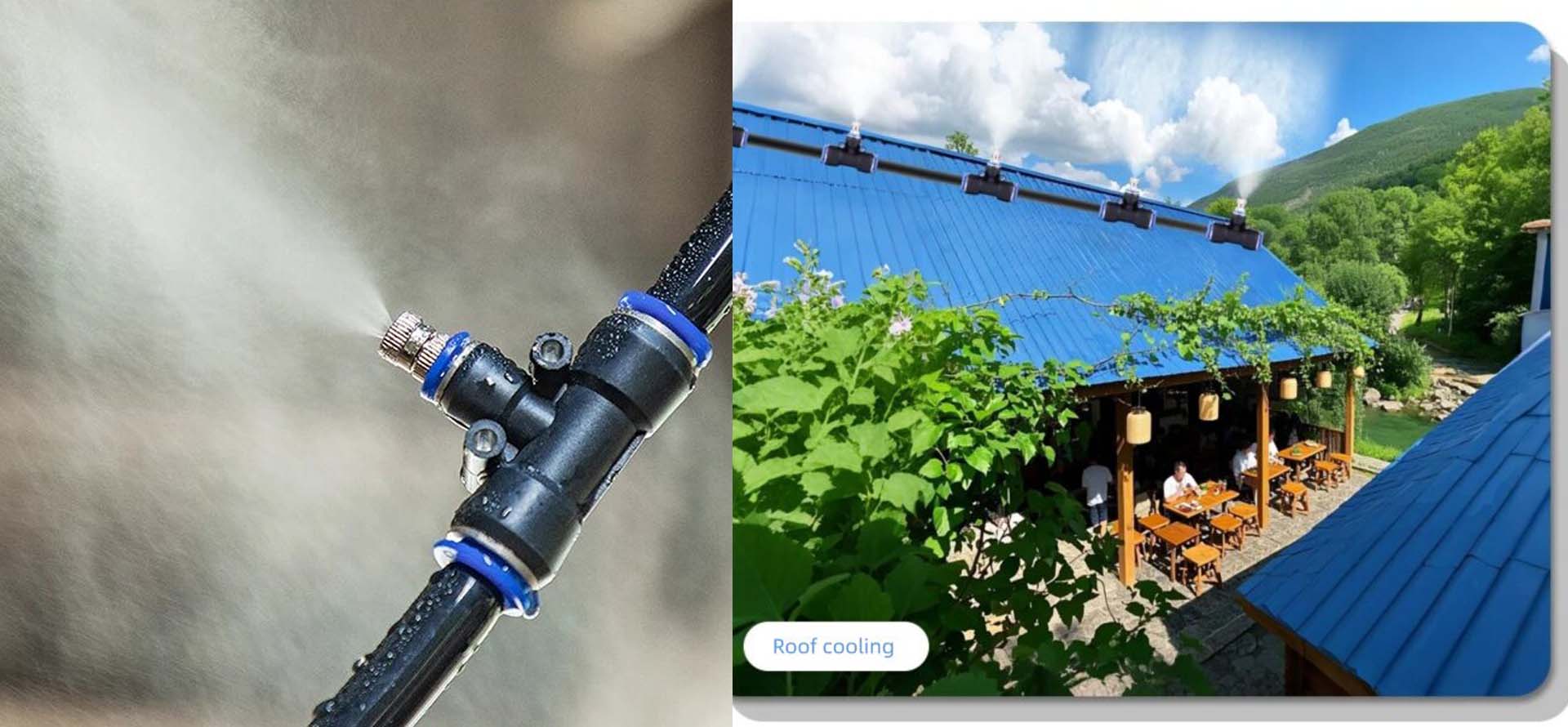

2. Atomization treatment: The pressurized water is sprayed out through a specially designed nozzle, and the small aperture of the nozzle breaks the water into tiny droplets in high-speed flow. These droplets have a larger surface area and can better come into contact with the air.

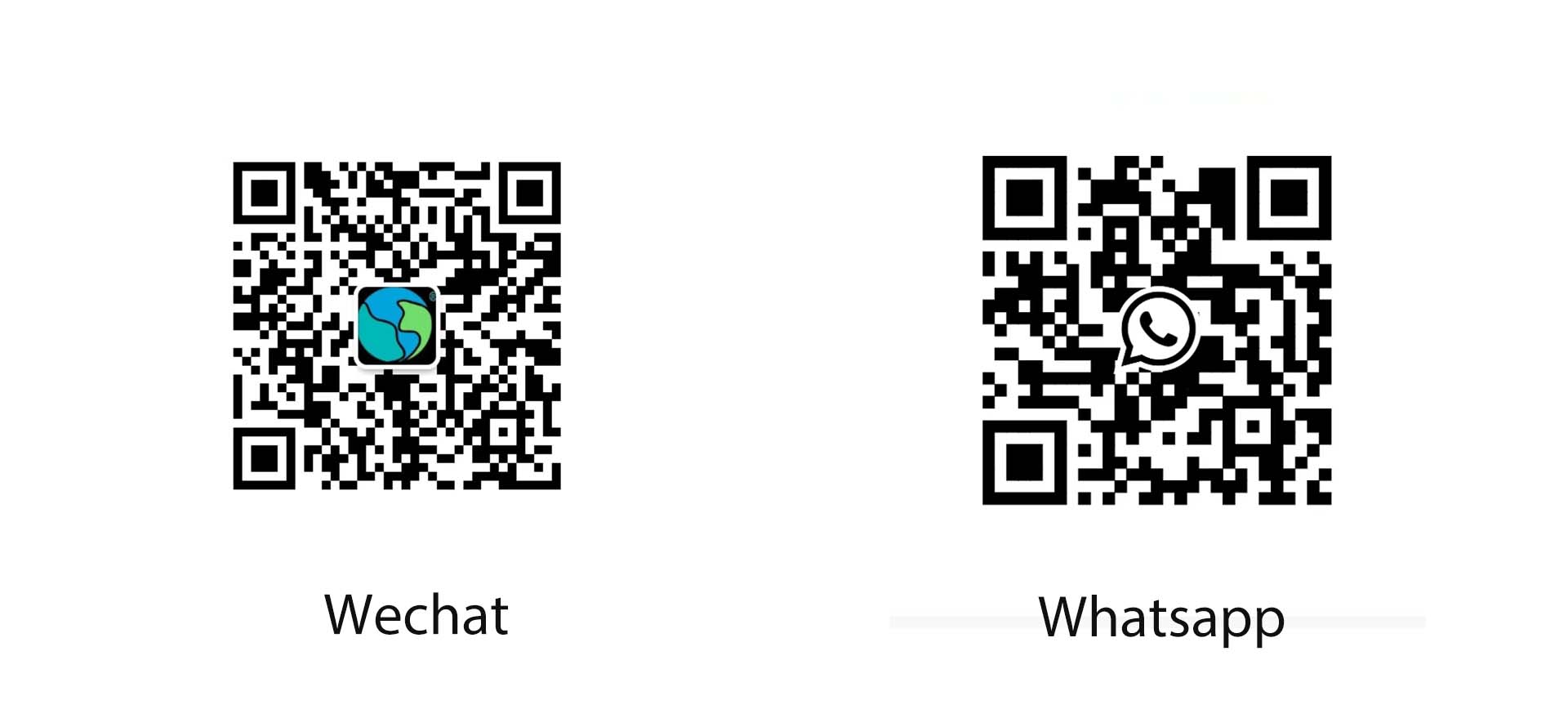

3. Diffusion and adsorption: Small water mist particles rapidly diffuse in the air, forming a thin layer of water mist curtain. These water mist particles have strong adsorption capacity and can quickly adsorb pollutants such as dust particles and bacteria in the air, forming larger particle clusters.

4. Settlement and collection: Under the action of gravity, water droplets carrying dust particles will gradually settle to the ground or other collection equipment, thereby achieving the purpose of purifying the air.

Any device and machines need to be maintenance, so how to maintenance the high pressure spraying system?

In order to ensure the long-term stable operation and dust reduction effect of the high-altitude atomization spray system, regular maintenance and upkeep are required. The following are maintenance points:

1. Regular cleaning of equipment: Regularly clean the dirt on the outer surface of the equipment, including water pipes, nozzles, water pumps, and other components. When cleaning, be careful not to use corrosive or irritating cleaning agents to prevent damage to the surface of the equipment.

2. Check the nozzle and pipeline: Regularly check whether the nozzle is blocked, remove debris from the nozzle, and ensure that the water mist is uniform and delicate. At the same time, check whether there is any leakage in the pipeline, and if there are any leakage points, clean and repair them in a timely manner.

3. Check water quality and replace filter element: Due to the small nozzle aperture, there are certain requirements for water quality. Regularly check the water quality. If the water quality is poor, a filtering device needs to be installed and the filter element in the sprinkler system needs to be replaced regularly to ensure clean water quality and prevent impurities from entering the system and affecting the sprinkler effect.

4. Check the water pump and control circuit: Regularly inspect the working condition of the water pump, including wear and tear, sealing performance, etc. At the same time, check whether the control circuit is normal to ensure the normal operation of the equipment’s automation control.

5. Seasonal maintenance: Maintain according to the characteristics of different seasons. For example, in winter, it is important to take measures to prevent freezing and cracking of pipelines; Check the heat dissipation of the equipment in summer to avoid overheating and damaging the equipment.

6. Training and standardized operation: Train operators to master the correct operating methods and precautions, and avoid harm to equipment caused by improper operation. At the same time, establish standardized operating procedures and maintenance systems to ensure the normal operation of equipment

For more information, please contact for more information: