What is the low temperature evaporation equipment?

The low temperature evaporation equipment is a device that separates and evaporates the water in the electroplating bath solution through the evaporation principle, thereby concentrating and recovering the metal salts and other useful components in it. The equipment is used for the treatment of high-concentration wastewater and resource recovery in the electroplating industry

Which electroplating processes are applicable?

- galvanizing solution–Main recycled resources: zinc sulfate, potassium chloride, zinc oxide, silver chloride, aluminium sulfate, sodium zincate, sodium zinc fluoride, boric acid, etc., organic additives (such as brighteners, stabilizers, etc.)

- nickel-plating solution–Main recycled resources: nickel sulfate, nickel chloride, boric acid Organic additives (such as brighteners, stabilizers, etc.) and inorganic salts (such as sodium chloride, sodium sulfate, etc.)

- chromium-plating solution–Main recycled resources: chromic acid (chromic anhydride), sulfuric acid, sodium chloride, organic additives (such as wetting agents, stabilizers, etc.)

- copper plating solution–Main recycled resources: copper sulfate, copper chloride, copper pyrophosphate, organic additives (such as brighteners, leveling agents, etc.), inorganic salts (such as sodium sulfate, sodium chloride, etc.)

- gold plating solution–Main recycled resources: potassium gold cyanide (or sodium gold fluoride), sodium nitride, potassium sulfate, organic additives (such as brighteners, stabilizers, etc.)

- Cadmium plating solution–Main recycled resources: cadmium sulfate, cadmium chloride, cadmium cyanide, organic additives (such as brighteners, brighteners, etc.)

- Tin plating solution–Main recycled resources: stannous sulfate, stannous fluoroborate, organic additives (such as brighteners, stabilizers, etc.), inorganic salts (such as sodium sulfate, sodium fluoride, etc.)

- silver plating solution–Main recycled resources: potassium silver per (or sodium silver ), sodium fluoride, potassium sulfate, organic additives (such as brighteners, stabilizers, etc.)

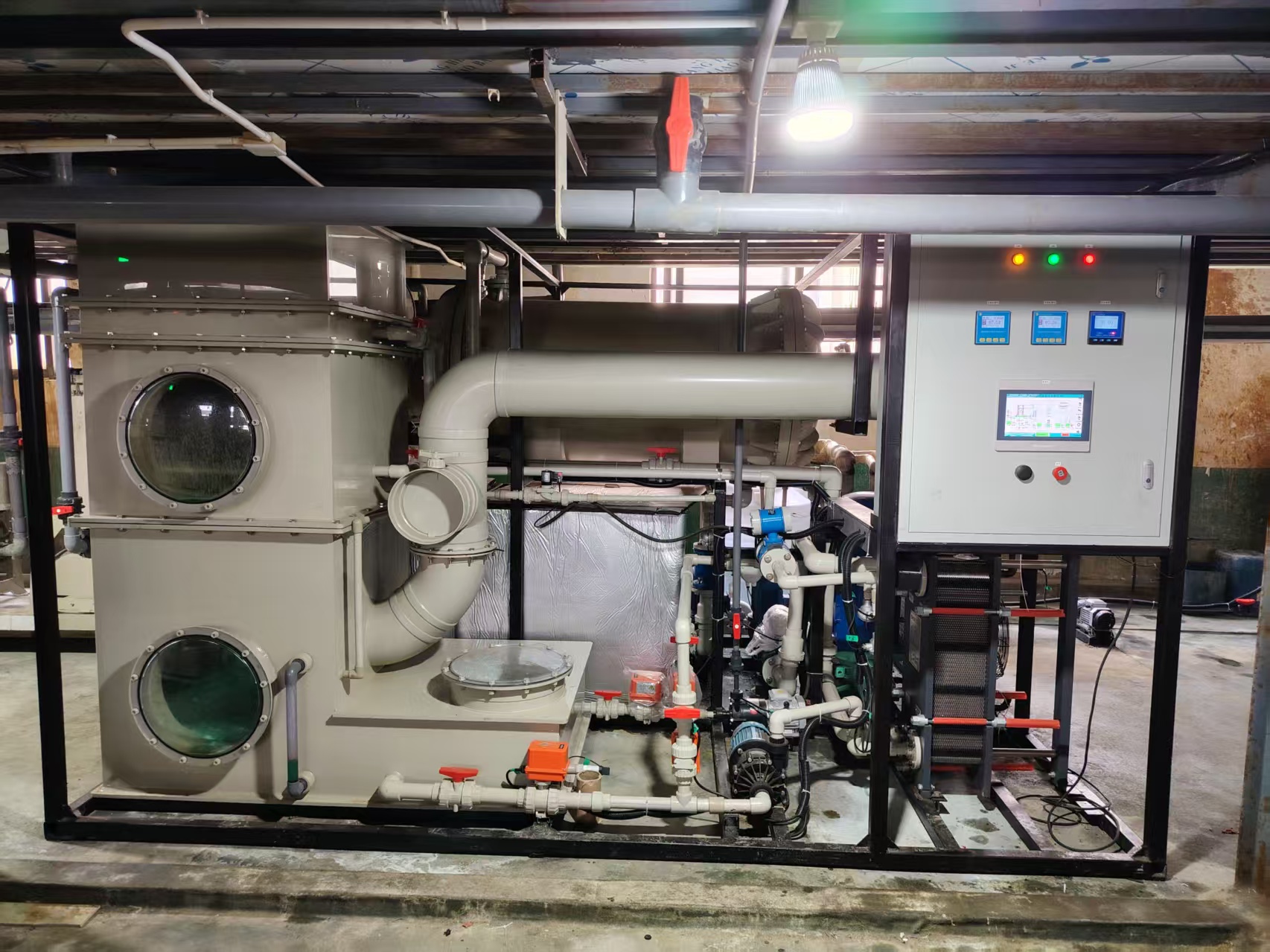

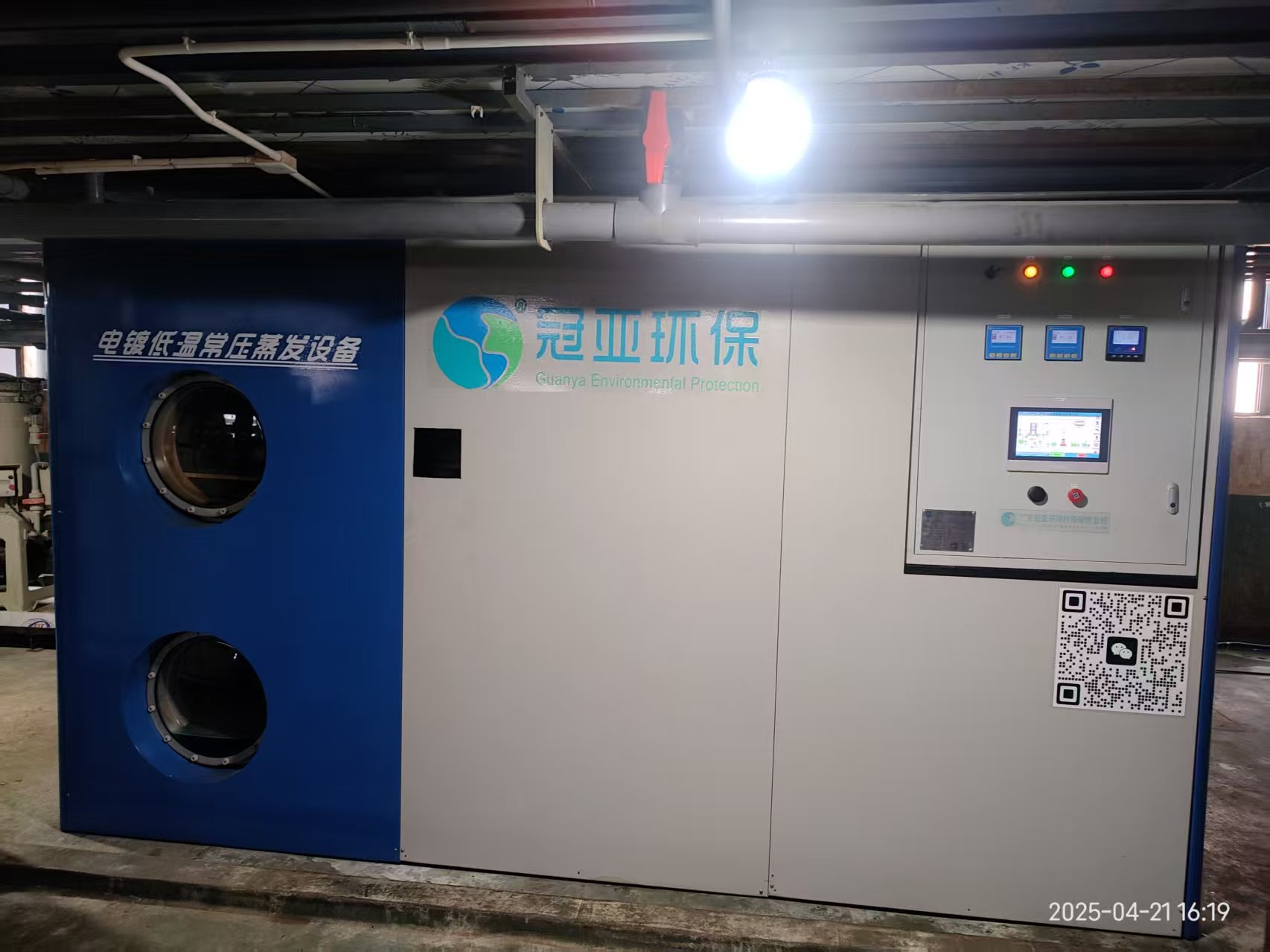

The electroplating solution evaporation integrated equipment is specially designed for the electroplating industry.

- Modularization–The equipment is highly integrated and can be installed either below the electroplating line or in an open space near the electroplating line. The modular equipment weighs a total of 2.5 tons, covers an area of approximately 9 square meters, and has a height of 2 meters

- Corrosion Resistance–The equipment adopts low-temperature and atmospheric pressure technology, and the main internal components are made of polytetrafluoroethylene,PPH,Made of corrosion-resistant materials such as graphite, it can easily withstand corrosion from plating solutions and greatly extend the service life of equipment

- Visualization-The equipment operates in a mist discharge mode, without generating evaporation waste liquid or exhaust gas. The internal strong circulation of the plating solution is visualized, directly separating the main salts and organic solutions from the water in the electroplating solution

- The produced water is reused–After the water in the electroplating solution processed by the equipment is separated, the salt content of the electroplating solution increases. The separated product water can be collected and reused. The measured conductivity of the recovered product water is as low as 13us/cm (taking nickel plating as an example)

- Exclusive patented technology–The relevant equipment company holds multiple R&D patent technologies, including invention patents, utility model patent technologies, and copyright certificates

- Achieve complete automation-The equipment is designed specifically for the plating line, achieving full automation without the need for personnel to stand by. It will automatically shut down when there is no plating solution treatment and in case of faults. It can also be remotely controlled via an APP

- Environmental protection and zero emissions–The equipment only requires electricity, no chemicals need to be added, and there is no need to connect to natural gas or steam boilers. No tail gas is generated, truly achieving circular mist emission.

- Operating at low temperature and normal pressure–The maximum operating temperature of the equipment materials is 50 degrees Celsius, the pressure of the logistics pipeline is only 0.2Mpa, and the evaporative condensation system operates at a low temperature and normal pressure, which is safe and reliable

- Authorized certification–The equipment has passed the ISO90001 quality system certification, passed multiple tests, and the produced water meets the enterprise’s reuse standards

What can be done for electroplating enterprises?

The first is to save the raw material cost of electroplating solution for enterprises

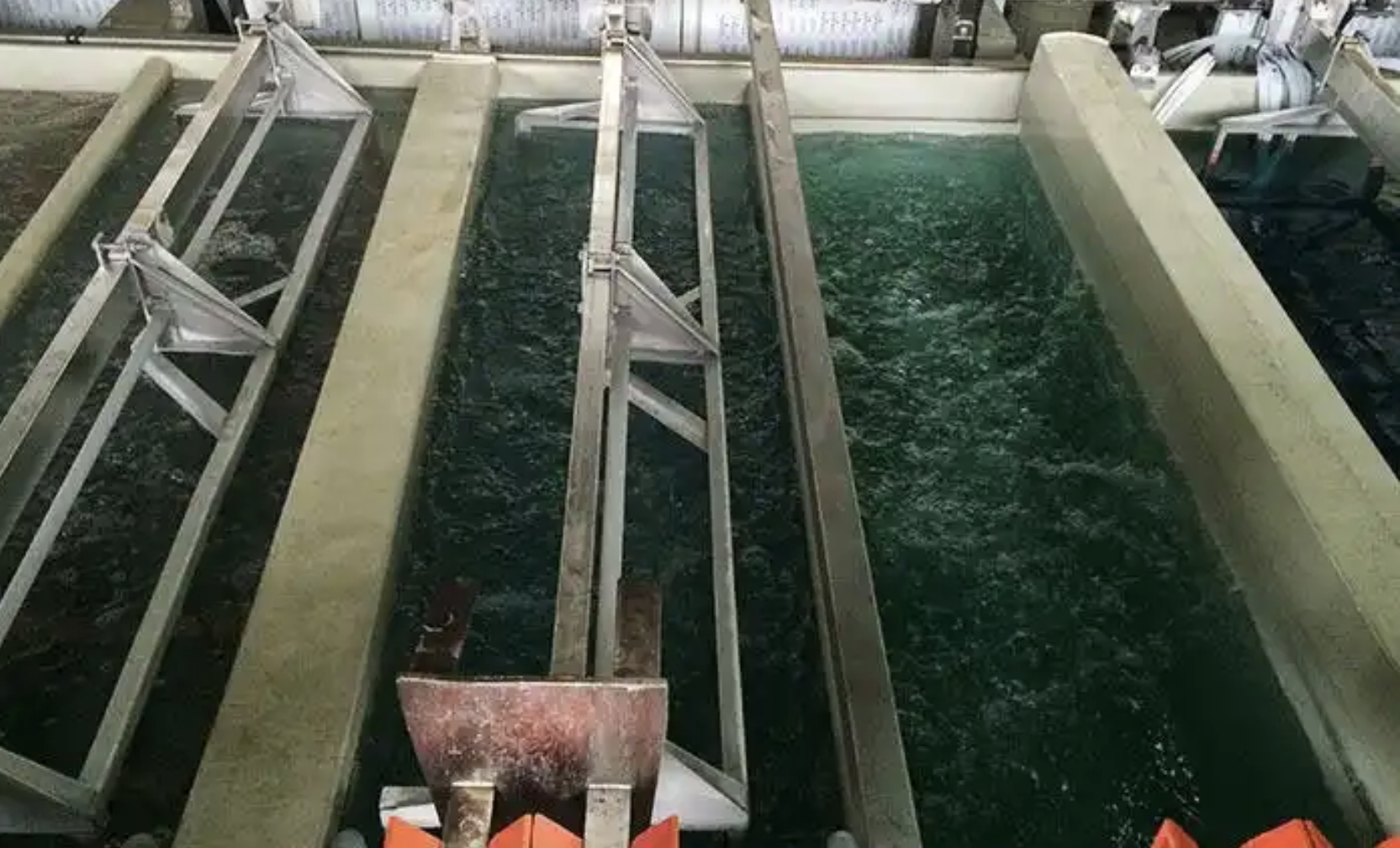

The evaporation and concentration recovery and treatment technology, the surplus or waste electroplating solution generated during the electroplating production process is collected. By using a corrosion-resistant low-temperature atmospheric pressure evaporator, the plating solution containing a large amount of metal salts can be concentrated, increasing the metal salt content of the plating solution, and then put back into the electroplating tank for use to supplement the concentration of the electroplating tank solution.

The second helps enterprises save water for cleaning plated parts

The water extracted by the evaporation equipment and the surface activator mixture can be used as the cleaning water for the plated parts before entering the electroplating tank. This is because the water extracted by the evaporation equipment contains surfactants, which play a very good role in cleaning the surface of the plated parts. Moreover, the components come from the electroplating tank. Even if the residues on the surface of the plated parts are brought into the electroplating tank after cleaning, it will not have any impact on the plated parts. Because the cleaning water comes from the by-product of the concentrated plating solution, that is, the cleaning water of the plated parts is saved

The third is to reduce the amount of hazardous waste generated by enterprises

In traditional electroplating wastewater treatment, reducing agents, acids, bases, oxidants and other chemicals are added. Therefore, the types of substances in electroplating sludge are very diverse and the composition is also very complex. Electroplating sludge is a solid waste that is inevitably produced in the wastewater treatment process of electroplating plants and is also a major reason for the high production costs of enterprises. The low-temperature and atmospheric pressure evaporation process can significantly reduce the generation of hazardous waste, saving enterprises the high cost of hazardous waste transfer and treatment

Welcome to contact us for more information.